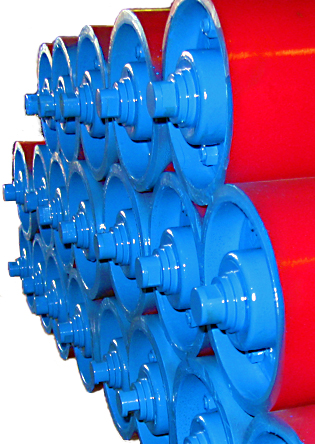

The last roller you'll ever need.

You're in the material-handling industry. Your conveyor system needs rollers, but you're tired of the wasteful replacements your current system requires. You don't think it makes sense to replace whole idlers when it seems so much of the product can be recycled.

Neither do we.

Elite Roller Manufacturing's award-winning products are changing the way the conveyor component industry thinks. Our unique four-bearing technology works with any system, outlasts the competition and allows us to quickly refurbish our rollers at a fraction of the cost of new replacements with a minimal amount of waste. When you bring our rollers back for refurbishing, 90% of the materials are reused.

How do we do it?

Our reuseable four-bearing axle assembly allows the Elite roller to run up to three times longer than the competition. This also allows the roller to operate in more severe applicatons.

There is no welding involved. Two hubs are pressed together on a support tube, which is then pushed through another tube and bolted on each end.

Each roller's damaged can is effortlessly replaced in a matter of minutes. In fact, any damaged part of the roller can be replaced. Purchasing only the replacement parts you need instead of complete idlers again and again translates into a major cost savings for our customers.

Take the next step.

Peruse our website to learn more, or give us a shout. We're here to help, and we're confident in our ability to be the lasting green roller solution you need.

Take control of your conveyor system with the smartest roller in the industry.

See how our patented roller engineering can save you money while having a positive impact on the world around us.

Need help? Check out our help page, or feel free to contact us with any questions you may have.